From Defect Detection to Predictive Maintenance: Manufacturing & Industrial Data Annotation

Converting manufacturing workflows into structured data that enables autonomous quality control and condition-based maintenance systems.

Precise Annotation for Production Lines, Equipment & Quality Checks

Manufacturing environments are full of motion, machinery, and fast-paced operations, making raw data hard to use without structure. We annotate every frame, part, and process with precision, labeling defects, tool positions, equipment states, and workflow steps. From production lines to machine dashboards, our annotations help organize industrial visuals into clean, usable datasets that support consistent monitoring, analysis, and operational control.

Labeling the Moving Parts of Modern Manufacturing

Manufacturing environments produce continuous streams of visual and sensor data, from high-speed production lines to quality checks on microscopic parts. Pixel Annotation specializes in manufacturing data annotation and industrial process labeling across a wide range of sectors, including automotive, electronics, heavy machinery, textiles, and food & beverage.

At Pixel Annotation, our workflows include 2D bounding box annotation for part tracking, polygon labeling for surface defects, instance segmentation for object differentiation, and video annotation for step-by-step process analysis. We label visual data from assembly lines, inspection stations, robotics footage, and equipment dashboards, capturing everything from product quality to worker movements. Our services also support worker safety analysis, PPE compliance monitoring, workflow labeling, and tool usage tracking, ensuring a complete, structured view of manufacturing operations.

With experience across diverse industrial settings, whether for precision manufacturing or high-volume production, Pixel annotation helps transform raw visuals into structured datasets ready for review, analysis, and automation.

Our Manufacturing Annotation Services

We annotate product flaws and quality checkpoints across manufacturing stages, including cracks, misalignments, incomplete assemblies, and surface irregularities, using techniques like 2d bounding boxes, polygon image annotation, and frame-by-frame video annotation. These datasets help build automated systems that inspect for defects, validate quality standards, and reduce manual checks on production lines.

We annotate tools, component positions, hand movements, and production steps using video and temporal annotation. This supports real-time monitoring, flags deviations from standard procedures, and enhances visibility across automated and semi-automated assembly lines.

We annotate packaging formats, text placement, barcode presence, and label accuracy to support final-stage quality control. These datasets help detect mislabels, validate regulatory compliance, and prevent costly packaging errors before distribution.

We provide detailed annotation for object detection, pose estimation, and robot-tool interaction across industrial robotics workflows. From food sorting to part alignment, our data helps train robotic systems to perform tasks precisely in real-time, high-speed manufacturing environments.

Our annotation captures human movement, PPE detection, and proximity to machinery or hazard zones. These datasets help improve workplace safety, ensure regulatory compliance, and power systems that prevent incidents through smart monitoring.

Why Choose Pixel Annotation?

In-House Annotators Trained for Every Industry

Transforming complex medical images into precisely labeled data that powers healthcare AI solutions.

Expert-Reviewed Labels Across All Domains

Transforming complex medical images into precisely labeled data that powers healthcare AI solutions.

On-Time Delivery Without Quality Trade-Offs

Transforming complex medical images into precisely labeled data that powers healthcare AI solutions.

Secure Annotation with Full Data Privacy

Transforming complex medical images into precisely labeled data that powers healthcare AI solutions.

Industry Use Cases

We annotate scratches, cracks, and deformities to train models that detect product defects on high-speed lines.

QR and barcode regions are precisely labeled for inventory tracking and automated packaging verification.

We annotate waste materials to enable cleanliness monitoring and smart waste management on factory floors.

Using keypoint

annotation, we track worker posture and movements to identify ergonomic risks or improper task execution.

Get Your Data Annotated by Experts!

Transform your data into powerful insights with our expert annotation services tailored for your specific AI needs and goals.

Our Suite of Data Annotation Tools

Our Suite of Data Annotation Tools

Our Suite of Data Annotation Tools

Client Success Stories

Discover why businesses trust Pixel Annotation for their data annotation needs. Our clients share their experiences and insights, highlighting the quality, reliability, and support they receive from our team. Explore how we have become a valued partner in their AI development journey.

-

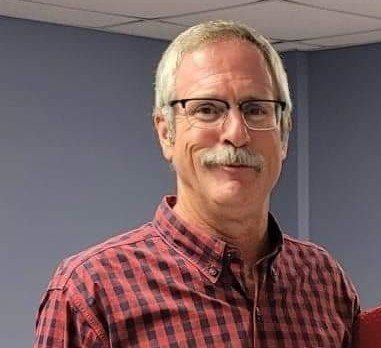

David ScottPixel Annotation's team exceeded our expectations with precise and detailed annotations that elevated our AI model's accuracy. Highly recommend them!Read more

David ScottPixel Annotation's team exceeded our expectations with precise and detailed annotations that elevated our AI model's accuracy. Highly recommend them!Read more -

John AndersonWe rely on Pixel Annotation for our data labeling needs, and they never disappoint. Consistently high-quality work and reliable turnaround times.Read more

John AndersonWe rely on Pixel Annotation for our data labeling needs, and they never disappoint. Consistently high-quality work and reliable turnaround times.Read more -

Nathan ParkerThanks to Pixel Annotation, our project timeline was faster, and our data quality is top-notch. The team truly understands precision in annotation!Read more

Nathan ParkerThanks to Pixel Annotation, our project timeline was faster, and our data quality is top-notch. The team truly understands precision in annotation!Read more -

Aaron CookIncredible service and impeccable attention to detail! The Pixel Annotation team went above and beyond to ensure our data was perfectly annotated.Read more

Aaron CookIncredible service and impeccable attention to detail! The Pixel Annotation team went above and beyond to ensure our data was perfectly annotated.Read more -

Sarah JohnsonPixel Annotation delivers quality and consistency every time. Their team's expertise in complex data annotation is outstanding!Read more

Sarah JohnsonPixel Annotation delivers quality and consistency every time. Their team's expertise in complex data annotation is outstanding!Read more -

Mason BarnesWorking with Pixel Annotation has been a game-changer. Their quality annotations have significantly improved our AI model's performance.Read more

Mason BarnesWorking with Pixel Annotation has been a game-changer. Their quality annotations have significantly improved our AI model's performance.Read more

Recent Blog

Get Started with High-Quality Data Annotation!

Fill out the form, and our team will reach out to discuss how we can meet your needs.